INDUSTRIAL EQUIPMENT BUSINESS DIVISION

Some companies build equipment. COMPLUS SYSTEMS delivers solutions.

We have spent years crafting a sophisticated enterprise with skilled teams and capabilities that allow us to take care of our customers’ complete needs, at any and every point in the life-cycle of their oil and natural gas facilities.

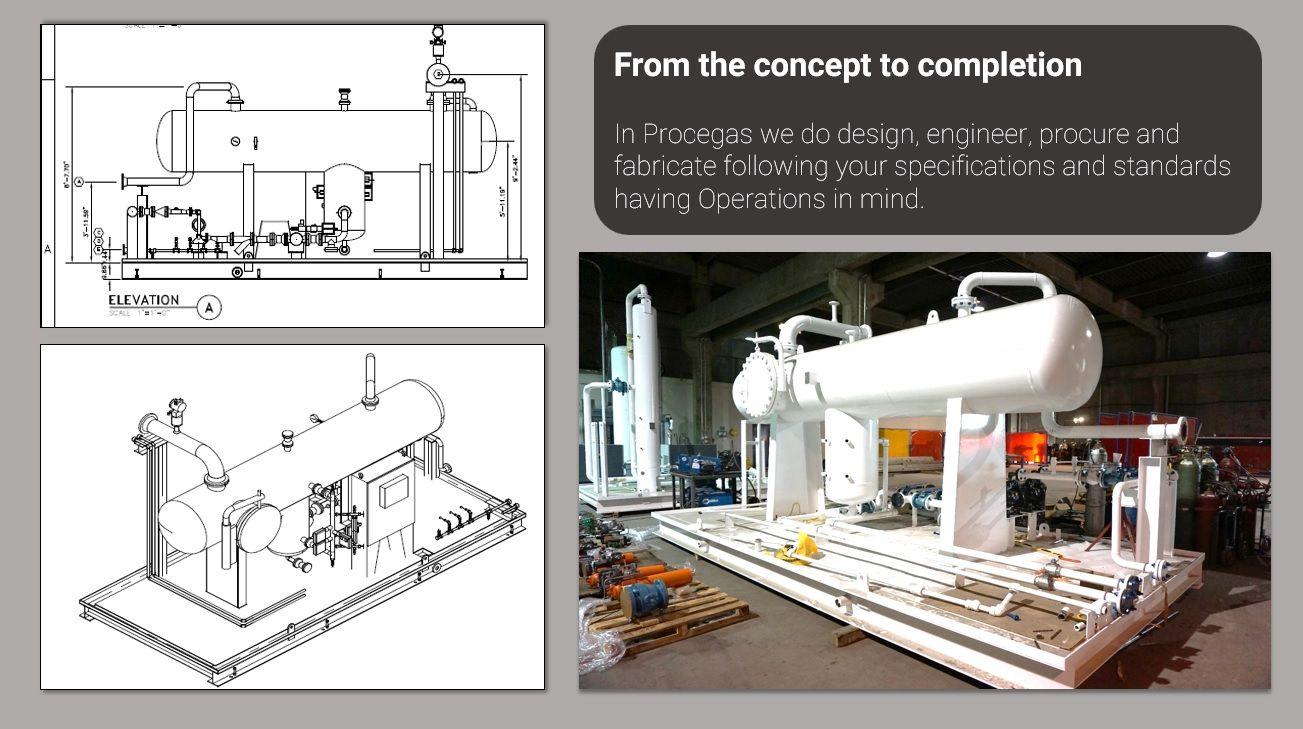

From the vision or initial drawings of your project all the way to operation and improvement of the facilities. And every step in-between. We will work with you anywhere you are doing business worldwide.

Our promise is to be your single source innovative solutions supplier. They include state-of-the-art manufacturing facility, continuously improving processes, deep expertise in engineering and operations, plus on-the-ground people, infrastructure and full capabilities in all our markets.

Our resources become your advantages. The most important is a customer-focused attitude geared to helping you get the greatest return out of the cash-producing assets that COMPLUS SYSTEMS manufactures and services for you.

Choosing COMPLUS SYSTEMS simplifies your supply chain, eliminates interface risk and reduces the concept-to-completion cycle time.

Going with the single source gets you thoroughly engineered, well-built equipment and facilities, a simplified supply chain, reduced interface risk, the fastest achievable time-line from concept through operations, cost certainty, and peace-of-mind that your systems will be kept at peak performance throughout their life-cycles.

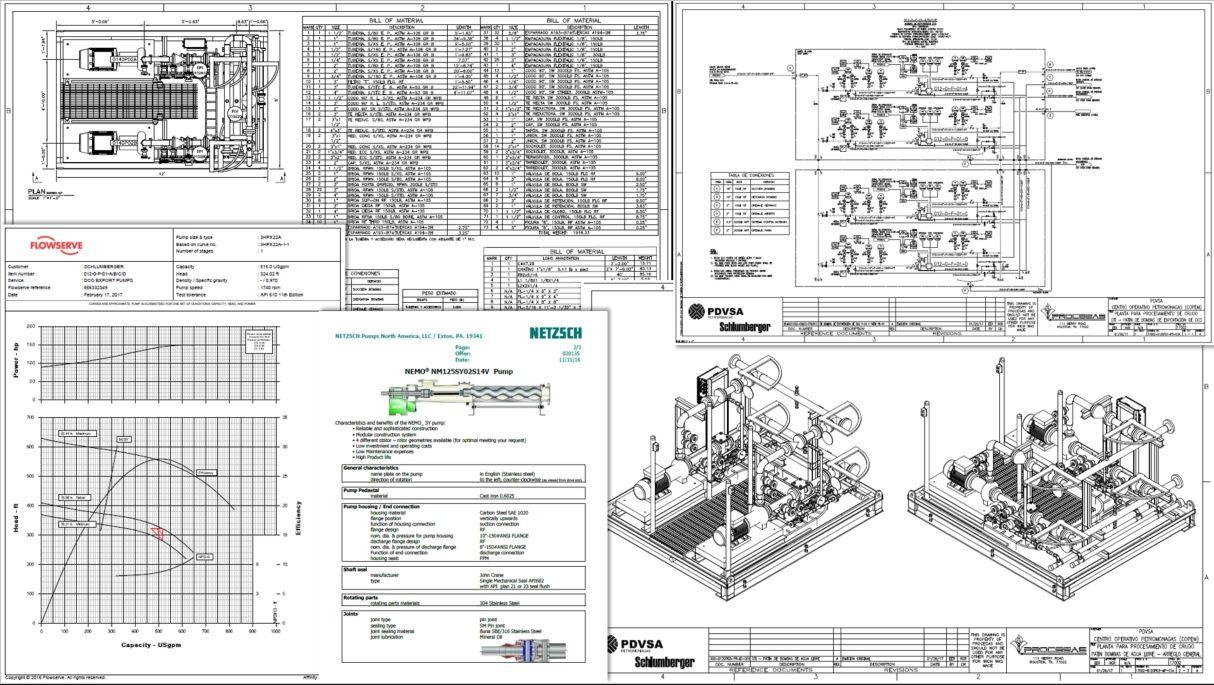

COMPLUS SYSTEMS is capable of executing projects from their concept to completion integrating design, engineering, purchasing, manufacturing, refurbishing, testing, packaging, export, installation support, commissioning and start-up. Our goal is to deliver integral custom made solutions primary oriented to the oil and gas industry, from the wellhead to the point of sale, supported by experienced and knowledgeable industry professionals, primarily focused on the operations efficiency, with strict compliance to the safety and environmental regulations.

COMPLUS SYSTEMS examples of areas of expertise:

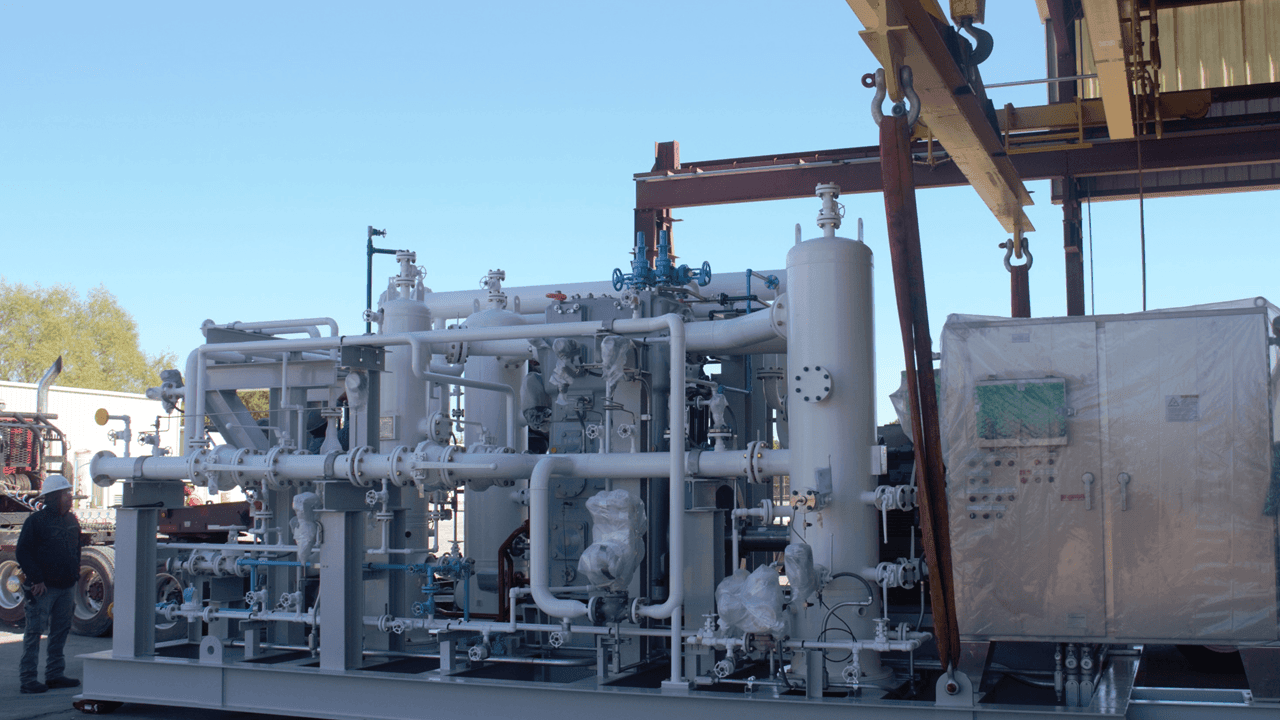

• Compression Packages for customers.

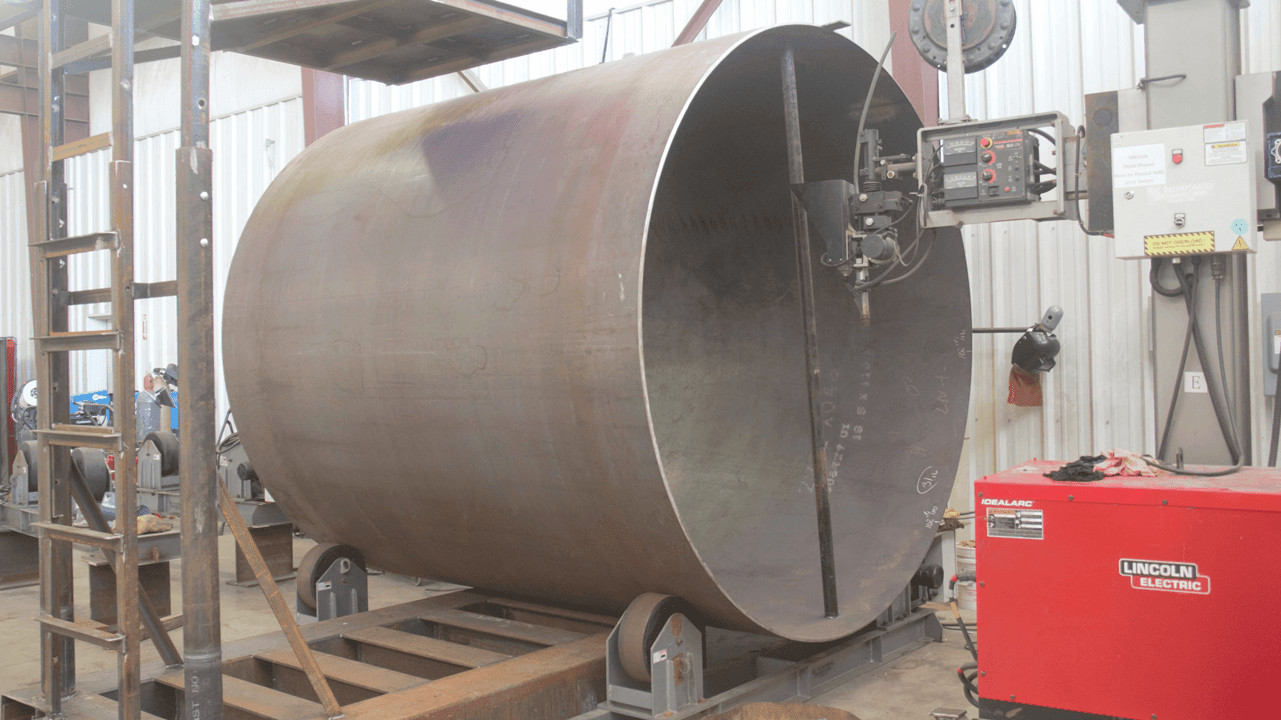

• Pressure vessels, separators, dampeners, KOD and scrubbers.

• Pump skids.

• An Energy Optimization Study and 3D Model.

• Service modules.

• Tenths of Vapor Recovery Units of different sizes for Flare Industries

COMPLUS SYSTEMS employs a small group of engineers, with vast expertise and different backgrounds within the oil & gas industry. This group of professionals whose background include the disciplines of instruments & automation, mechanical, electrical, design, process and systems, all come from the Operations/Field side of the Oil & Gas business.

Flexibility, thorough project understanding, gas compression expertise, clear and direct communications, in depth knowledge of the Oil & Gas industry processes and professionalism are some of the competitive advantages of COMPLUS SYSTEMS.

PRODUCTS

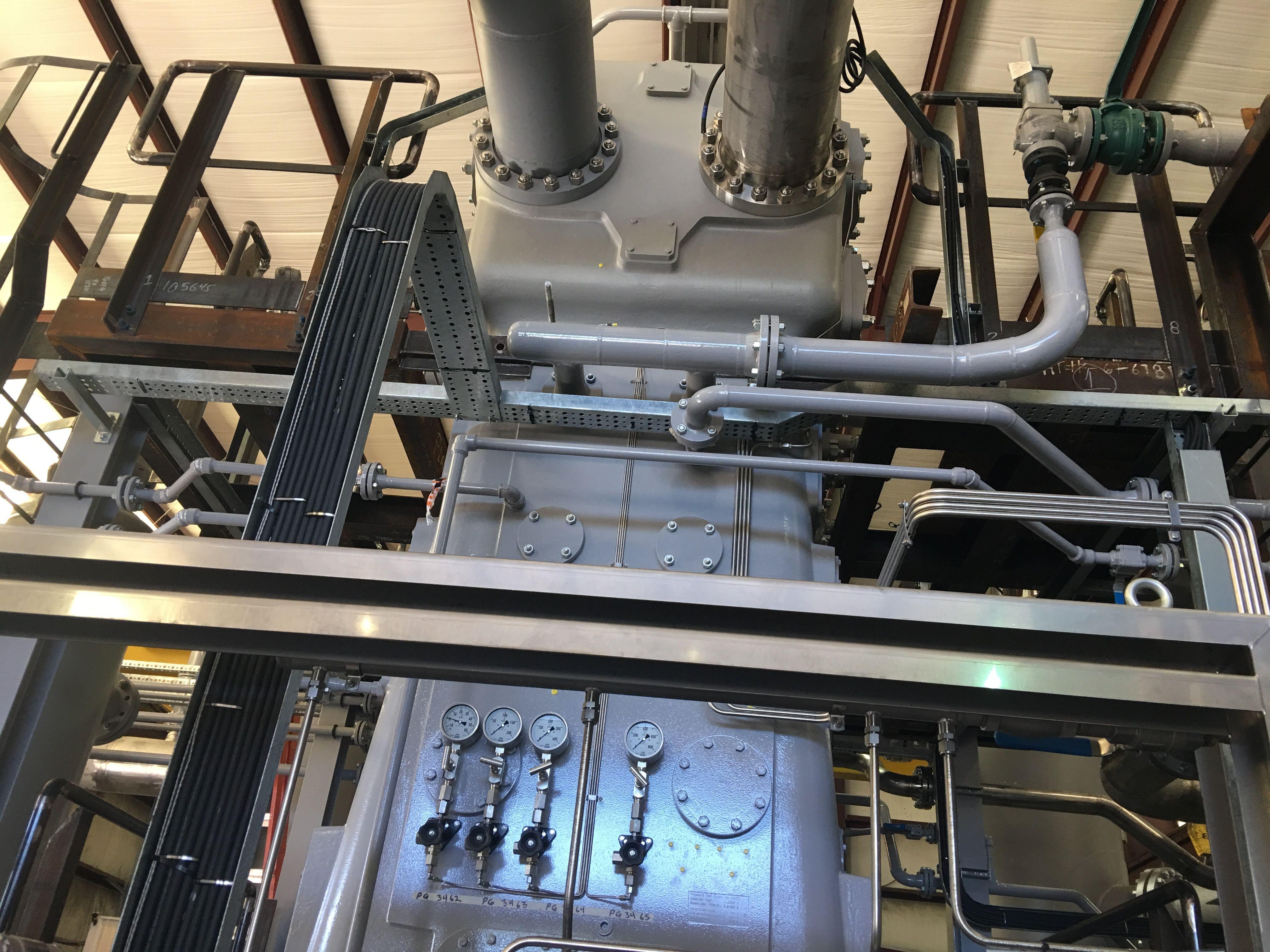

Compressors

Scopes

- Dampeners (ASME Sec VIII Div. 1 & 2)

- Scrubbers (ASME Sec VIII Div. 1 & 2)

- Piping Spools

- Mechanical Assembly

- Electrical & Instrumentation

- Control Panels

Clients

- Burckhardt Compression

- Exterran

- Sancus Energy

Compressor Package - Burckhardt Compression

Lotte Lake Compressor

Lotte Lake Compressor

Exterran Compressor

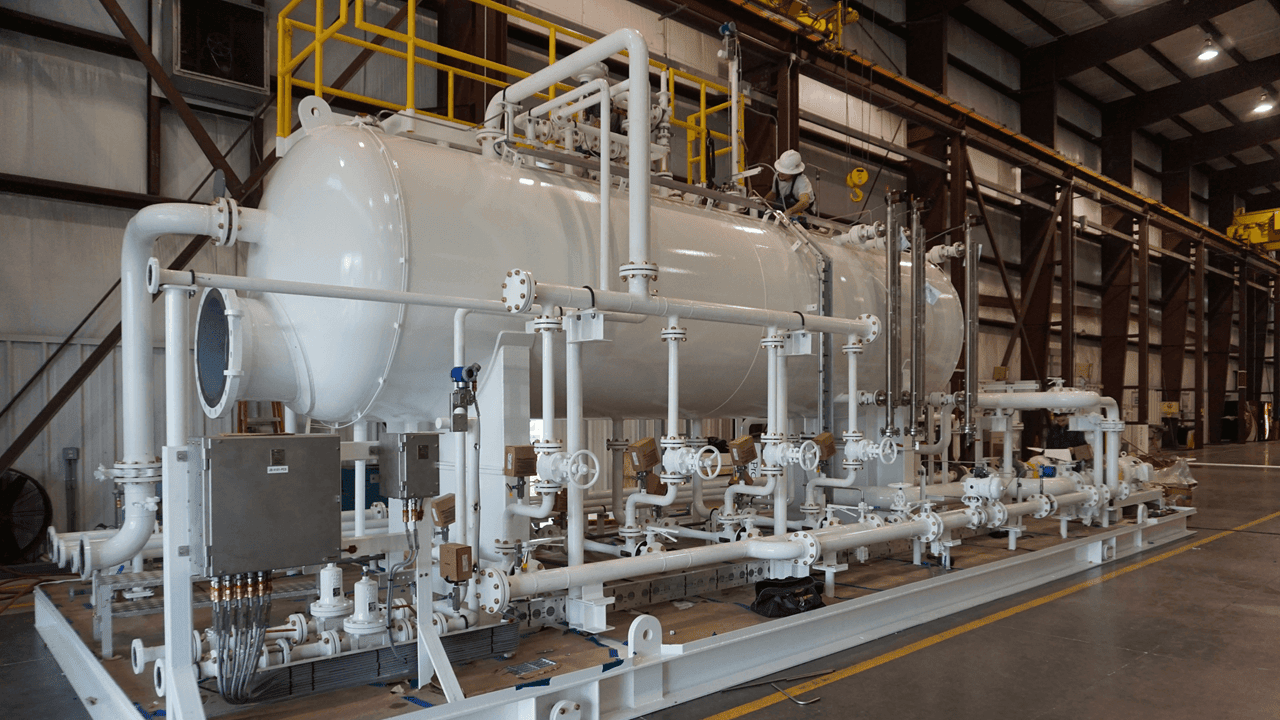

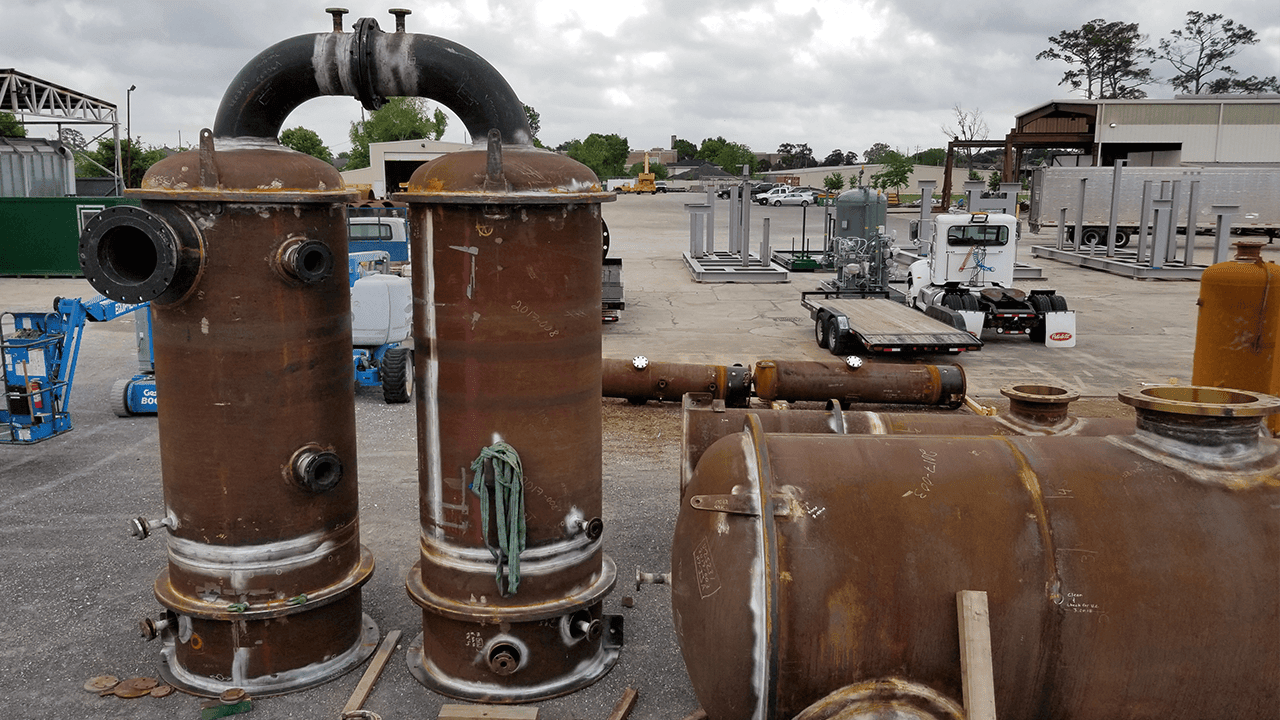

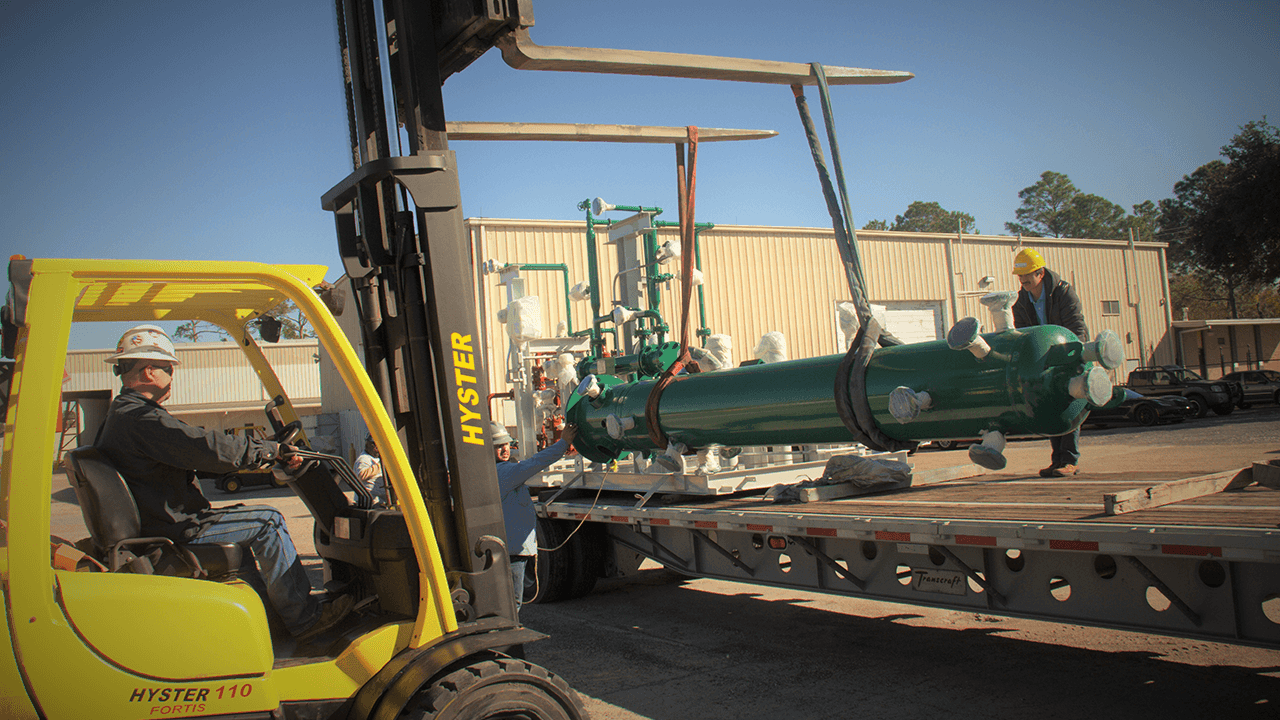

Process Skids

Scopes

- 2 Phase Separators (ASME Sec VII Div. 1 & 2)

- 3 Phase Separators (ASME Sec VII Div. 1 & 2)

- Scrubbers (ASME Sec VII Div. 1 & 2)

- Filters (ASME Sec VII Div. 1 & 2)

- Heat Exchangers (ASME Sec VII Div. 1 & 2)

- Direct Fire Heaters (ASME Sec VII Div. 1 & 2)

- Indirect Fire Heaters (ASME Sec VII Div. 1 & 2)

- Heaters Treaters (ASME Sec VII Div. 1 & 2)

- Desalters (ASME Sec VII Div. 1 & 2)

- Degaser (ASME Sec VII Div. 1 & 2)

- Corrugate Plate Interceptors (CPI) (ASME Sec VII Div. 1 & 2)

- Induced Gas Flotation Units (IGF) (ASME Sec VII Div. 1 & 2)

- Structural Steel Module Base

- Piping Spools

- Mechanical Assembly

- Electrical & Instrumentation

- Control Panels

- Vapor Recovery Units

Clients

- Prosep

- South Atlantic Petroleum Corporation

- Pan American Energy

- PEMEX

- 12 Eleven

- NPDC

- Aereon

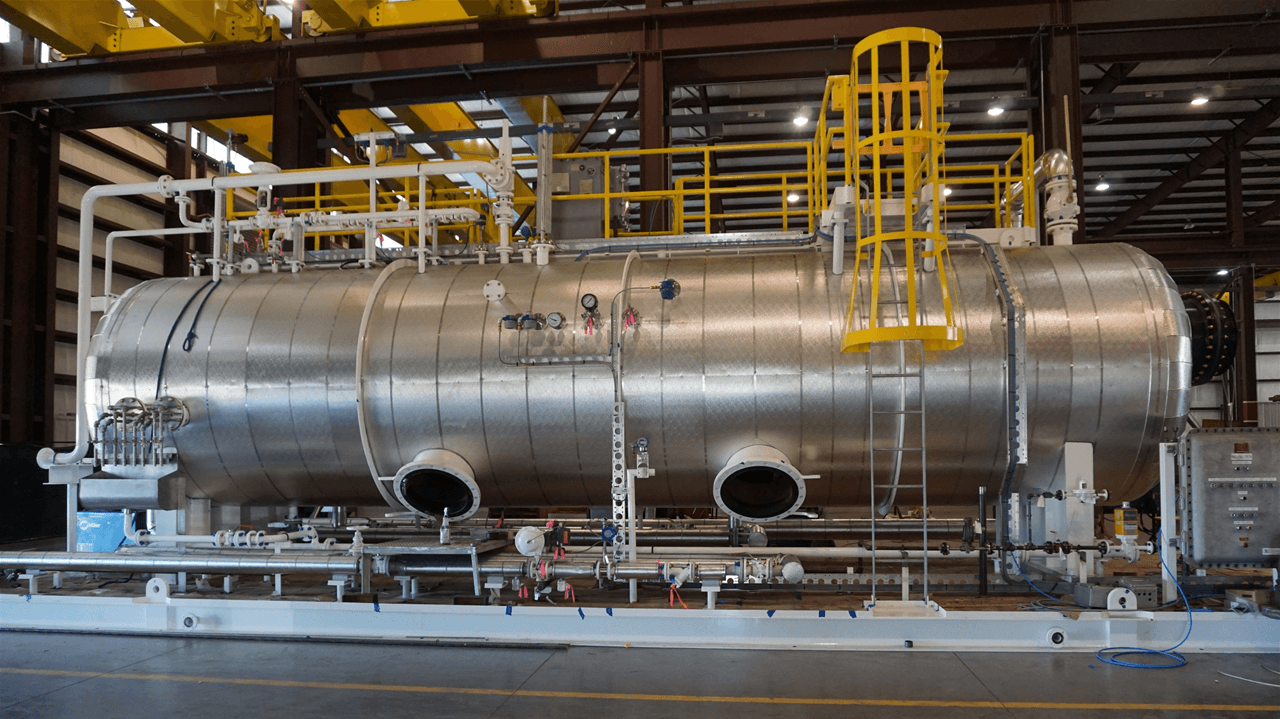

Customer: Obax

Gas Treatment

Scopes

- TEG Absorption Tower (ASME Sec VII Div. 1 & 2)

- Glycol Regeneration Skids

- Amine Towers (ASME Sec VII Div. 1 & 2)

- Piping Spools

- Fuel Gas Skids (ASME Sec VII Div. 1 & 2)

- Joule Thomsom Packages

- Heat Exchangers (ASME Sec VII Div. 1 & 2)

- Fully Assembled Packages

Customer: Burckhardt Compression

End User: Shell (Canada)

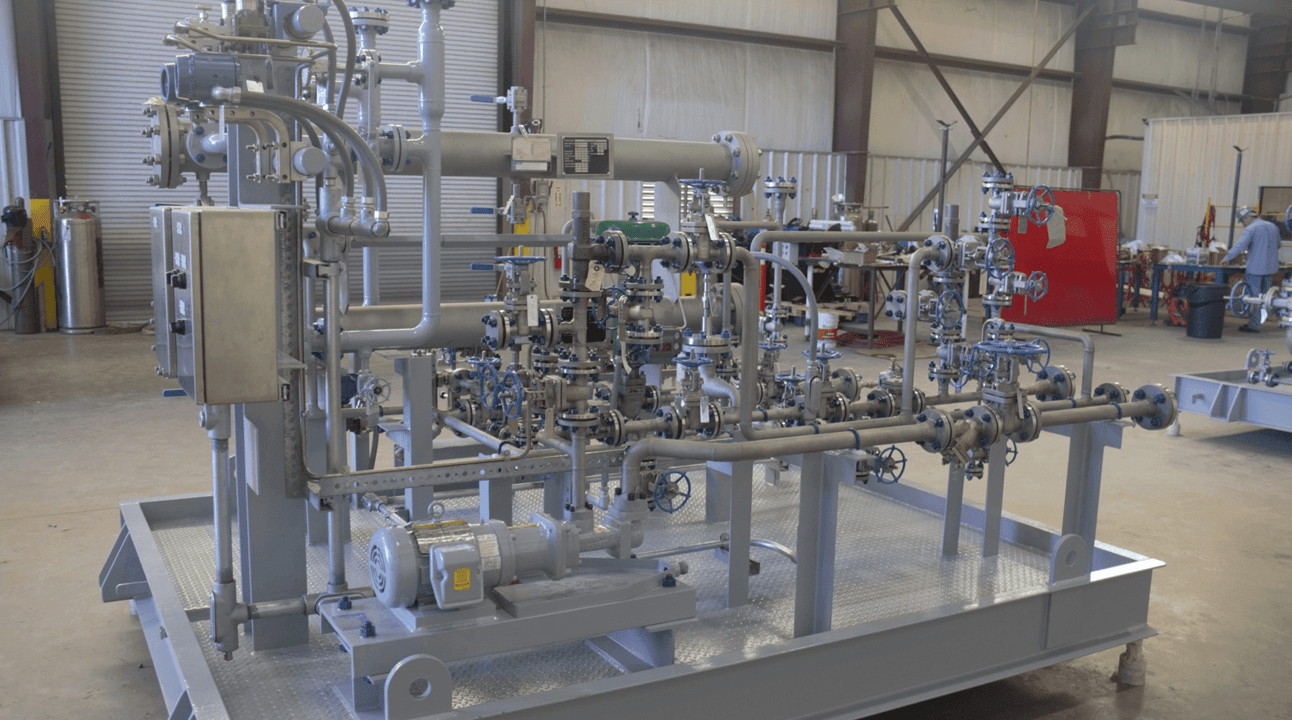

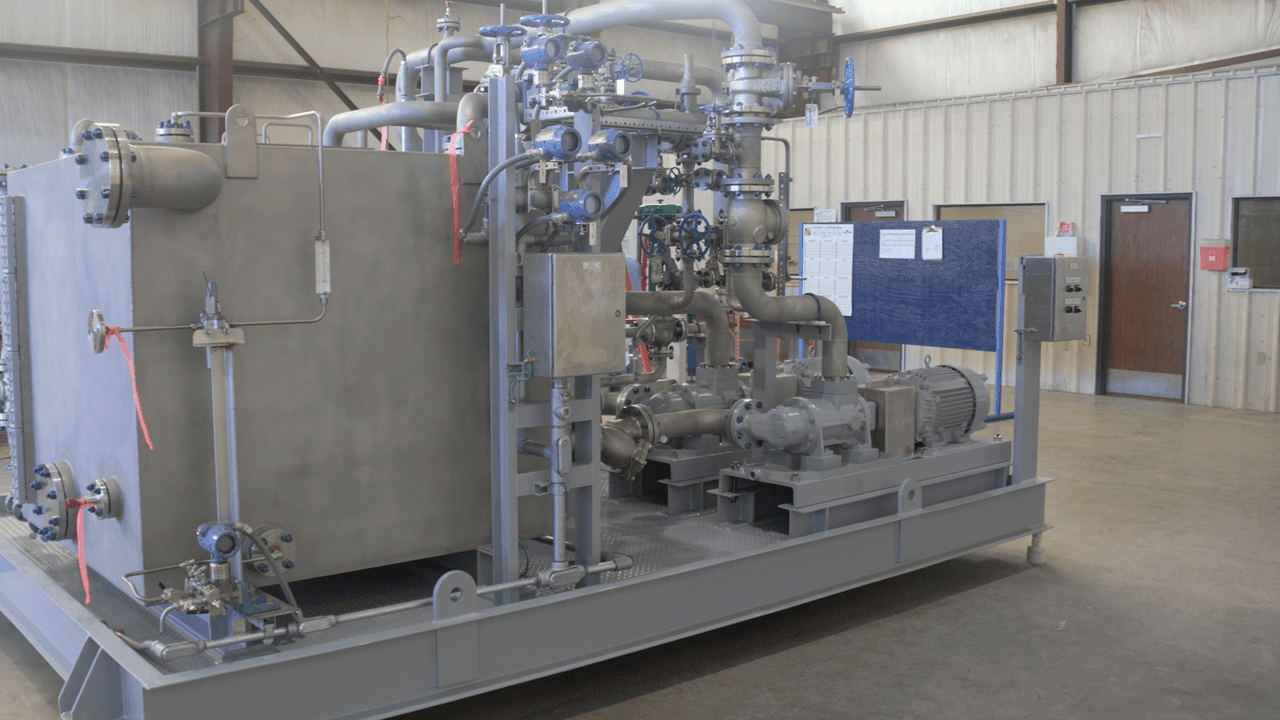

Pump Packages

Scopes

- Structural Steel Module Base

- Piping Spools

- Mechanical Assembly

- Electrical & Instrumentation

- Control Panels

Clients

- Schlumberger

- South Atlantic Petroleum Corporation

- NPDC

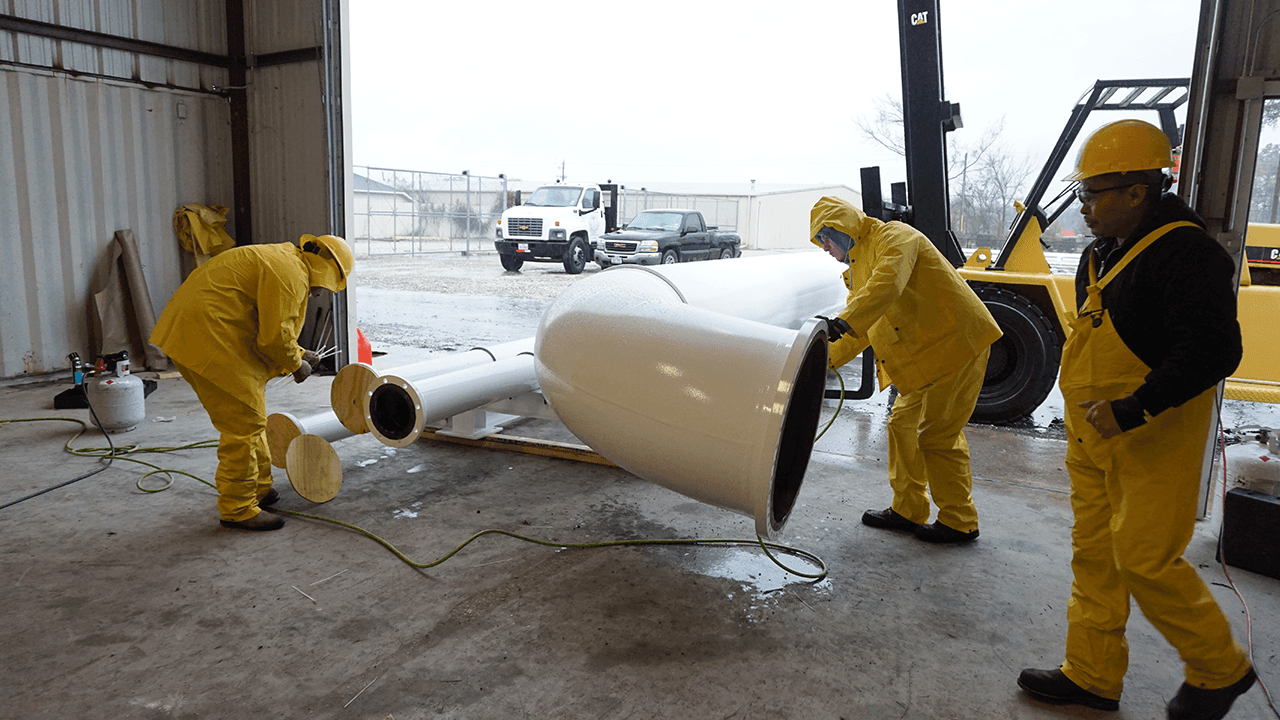

Others

Scopes

- Pressure Vessels Alterations

- Lifting Devices

- Sand Blast

- Paint

- Operational Test

- Field Services

Clients

Spartan Energy

Burckhardt Compression

Call us for any querry

EU +39 02 8719 9397

US +1 (830) 200 5119

Share our website

Please share our website on your social medias. THANKS !!!