EOR AlphaZyme D-300 Explained

AlphaZyme® is the evolution of microbe-biology technology for the purpose of improved oil-recovery. The product is engineered through a proprietary DNA-transfer process that involves impregnating a high-protein nutrient solution with selective DNA of oil-digesting microbes. This process results in an inert and water-soluble protein DNA-molecule, a non-living biological enzyme, specifically designed to act as an oil-releasing catalyst, capable of producing millions of reactions per second.

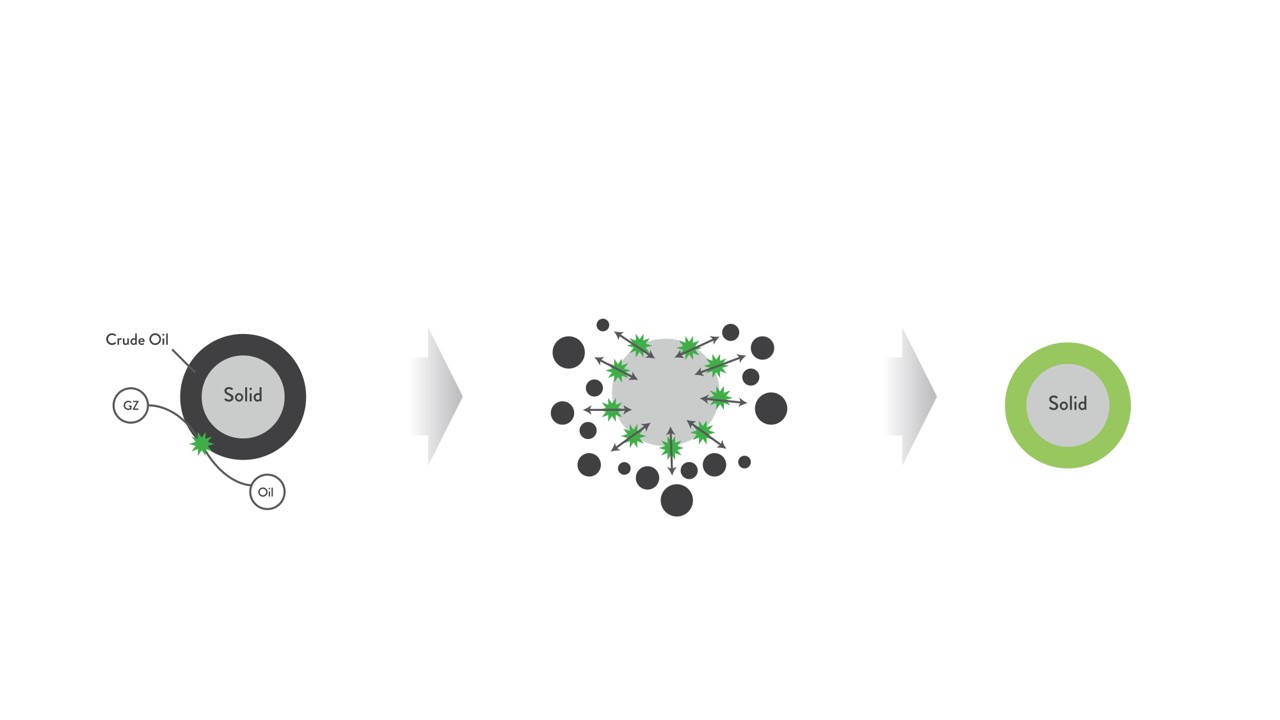

The enzymatic function of the catalyst is strictly limited to its interaction with hydrocarbons. As a true-catalyst, AlphaZyme® has the ability to perform its function repeatedly as a non-consumable agent, without loss of efficacy over time. The mechanism involves three components: H+, OH-, and an “active site”, which represents the proprietary DNA component. The H+ and OH- components form a polar part and the active site forms a non-ionic part. Upon contact with a hydrocarbon the non-ionic part allows the enzyme to penetrate the hydrocarbon, whereby the polar H+ and OH- components work to release microscopic droplets of oil.

The result of this unique behavior is a clean release of oil by relieving interfacial tension, improving contact angle and alleviating capillary pressures. This process is continuous over time and produces no byproducts of any kind. The hydrocarbon’s mobility is improved without impacting the hydrocarbon chain or changing viscosity. AlphaZyme’s® enzymatic catalyst function is capable of providing production impacts that have been measured in the field for durations in excess of 12 months after a single treatment.

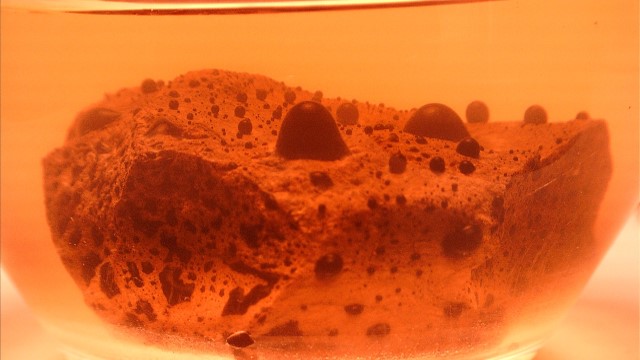

Video - How AlphaZyme D-300 works

As AlphaZyme reaches the oil / sand mixture, oil immediately releases from the substrate. Gravity then does its job; the pure oil separates and floats to surface while sediment is left behind on the surface floor.